COORDINATE MEASURING MACHINE HEXAGON

YAMAGUCHI is the official distributor of HEXAGON measuring machines in the Vietnamese market, specializing in providing high-precision industrial measurement solutions with the highest quality, along with professional consulting and technical support services.

Contact us to receive SPECIAL OFFERS from HEXAGON for the Coordinate Measuring Machine (CMM, 3D CMM, 3D measuring machine) line, exclusively for the Vietnamese market.

Nowadays, inspection and measurement play an extremely important role in the industrial manufacturing sector. These processes not only help ensure product quality and dimensional accuracy, but also contribute significantly to preventing and minimizing costs arising from reworking or discarding defective products. Among these, the 3D CMM measuring machine has emerged as an effective solution for inspection and measurement tasks. So, what exactly is a CMM – a Coordinate Measuring Machine? Let’s explore the details of this 3D coordinate measuring machine with Yamaguchi Vietnam in the article below.

What is a CMM? A CMM (Coordinate Measuring Machine) is a type of industrial metrology equipment used to measure the precision of mechanical components, parts, or finished products. This 3D measuring machine utilizes specialized sensors and control software to create a three-dimensional model of the object being measured, and provides important parameters such as dimensions, shape, and position. This allows the 3D coordinate measuring machine to inspect quality and ensure the accuracy of parts and products, while also improving efficiency and reducing errors in the manufacturing process.

CMMs (Coordinate Measuring Machines) are known by various names such as: 3D measuring machines, 3D CMMs, coordinate measuring machines, 3D coordinate measuring machines, dimensional measuring machines, etc.

_1.jpg)

For more information, visit: https://yamaguchi.vn/may-cmm-kieu-cau-glory-bridge-cmms

The Coordinate Measuring Machine (CMM) is a precision measurement tool that was developed during the 1950s and 1960s, a period when the emergence of digital computer technology offered significant potential for the advancement of measurement tools. Key milestones in the history of the CMM include:

1950-1960: The first prototypes of the 3D CMM were developed by leading information technology and measurement companies of the time, such as Brown & Sharpe in the USA, Ferranti in the UK, and DEA (Distribuzione Elettronica Applicata) in Italy. Initially, these CMMs were primarily used in military and aerospace applications, where high accuracy and reliability were crucial.

1960-1970: CMM technology continued to evolve with the integration of electronic sensors and precision probes, enabling measurements on complex and hard-to-reach surfaces.

1980: CMMs were further enhanced by incorporating optical and laser technologies, opening up new possibilities for non-contact measurement and height measurement.

.jpg)

Subsequently: With advancements in computer technology and the development of control software, CMMs have become more compact, user-friendly, and capable of higher precision. Coordinate measuring technology has been integrated with other technologies, such as optical, laser, and photoelectric technologies, improving the accuracy and reliability of CMMs.

Today, CMMs (Coordinate Measuring Machine) have become a crucial tool in the quality inspection process and in ensuring the precision of products across various industries.

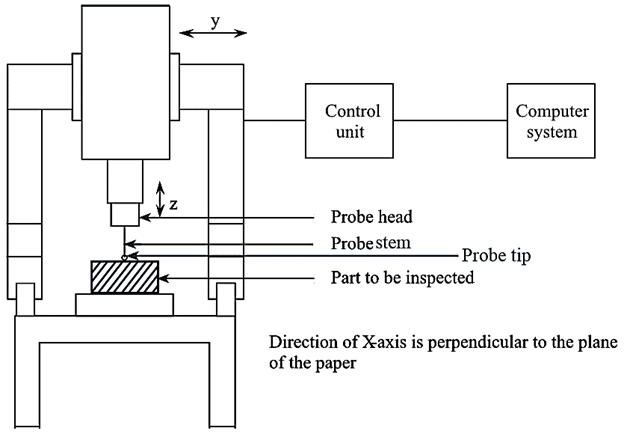

The structure of a CMM (coordinate measuring machine) can vary depending on the type and manufacturer, ranging from compact handheld CMMs to large-scale machines used in heavy industrial applications. However, the basic structure of a CMM typically includes the following main components:

Frame: The frame holds the mechanical parts of the machine and forms the main structure of the CMM. It is usually made of metal, ensuring the stability and rigidity required for precise measurements.

Measuring Table: This is a flat surface, sometimes equipped with slots or clamps to hold the samples to be measured. The table can move along multiple axes (X, Y, and Z) to measure in different directions.

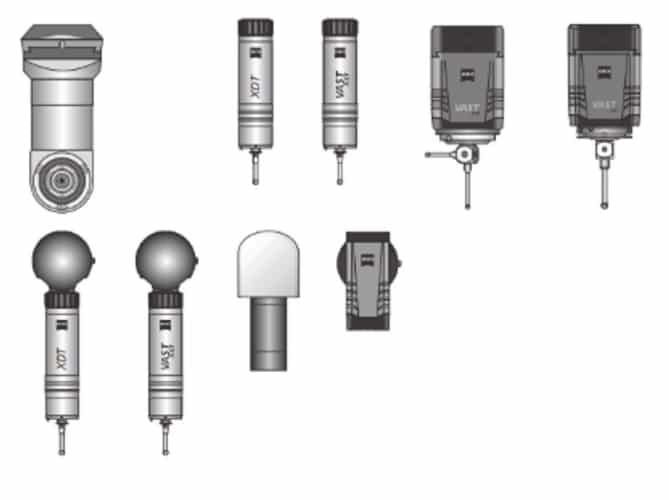

Probe: This device is mounted on the measuring table or an axis to measure points on the surface of the sample. The probe can be a touch probe, an optical probe, or a non-contact probe using technologies like spectroscopy, laser, or electromagnetism.

Measurement System: This electronic component includes sensors, controllers, and measuring software, allowing for the collection and processing of measurement data from the probe. The system is often integrated with specialized measurement software, enabling programmed measurements, calculation of measurement results, and display of measurement data on a computer screen.

Accessories: These include clamps, positioners, locating tools, dial indicators, and other accessories that help position and securely hold the sample on the measuring table.

A 3D CMM (coordinate measuring machine) operates by moving a measuring device along three axes, x-y-z, and uses sensors to record information about the position of the measuring device in three-dimensional space. The computer control software integrated with the measuring machine provides tools and functions to process data and display measurement results. Currently, some modern software can automatically generate measurement reports.

Various types of 3D CMMs (Coordinate Measuring Machine) are available in the market today, each with distinctive features suitable for different usage requirements. They can be classified based on the coordinate system used and the interaction between the probe and the surface of the part or product being measured.

Based on the coordinate system used:

Moving-bridge CMM: Includes both moving and fixed-bridge CMMs.

Cantilever CMM

L-shaped CMM

Optical CMM

Based on the interaction between the probe and the measured part or product:

Contact 3D CMM: Uses a physical probe that mechanically touches the surface of the part being measured.

Non-contact 3D CMM: Uses optical technology to accurately map details into a 3D model.

To determine which type of CMM is suitable for your production scale and product, let's explore more in the following content of this article with Yamaguchi.

The 3D CMM (Coordinate Measuring Machine - CMM) is a precision measurement tool used across various industries for measuring and inspecting manufacturing parts and components. With its ability to measure high precision and diverse geometric characteristics, the CMM has become a crucial tool in quality control processes, enhancing manufacturing efficiency, and achieving high accuracy and reliability in production.

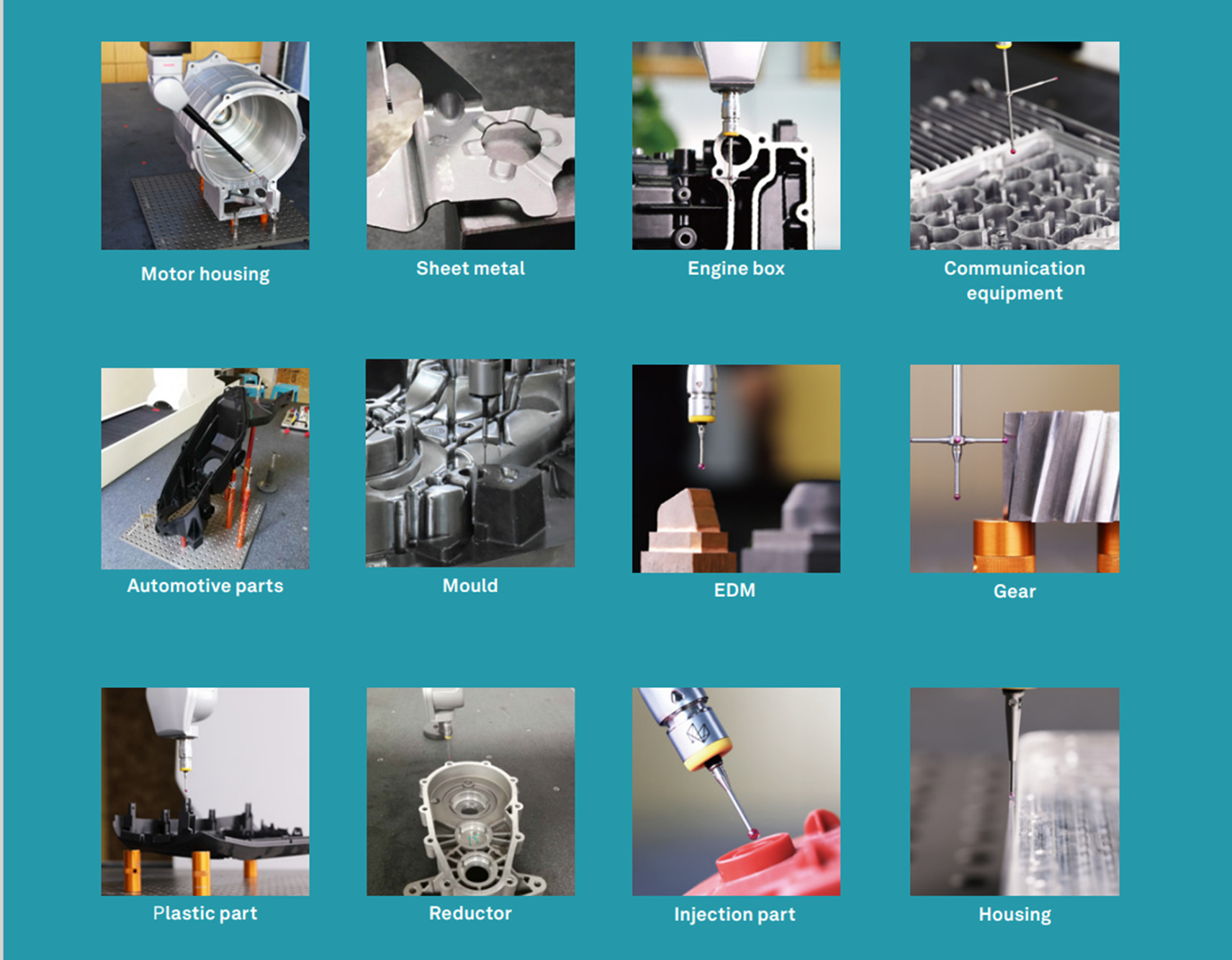

Here are some of the main applications of the CMM (coordinate measuring machine) in different industries:

Automotive Industry: The CMM is used to measure and inspect automotive parts such as engines, frames, brakes, suspension systems, and other components. This ensures the accuracy and reliability of the parts and controls quality during the automotive manufacturing process.

Aerospace and Space Industry: The CMM is utilized to inspect components of aircraft, rockets, satellites, and other aerospace and space equipment. These applications require extremely high precision and reliability during production to ensure the safety and performance of these devices.

Manufacturing Industry: The CMM is used in the production and inspection of manufacturing parts, including metal machining, plastic machining, woodworking, casting, and sheet metal processing. Applications include checking dimensions, shape, position, curvature, flatness, perpendicularity, and other parameters of manufactured parts to ensure their accuracy and reliability.

Medical Industry: The CMM is employed in the production and inspection of medical parts, including medical devices, surgical instruments, and precision mechanical components in healthcare.

The CMM (Coordinate Measuring Machine) is a widely used precision measurement tool in the industrial sector with a variety of applications. It not only supports product quality inspection and new product research and development but also contributes to the advancement and improvement of manufacturing processes. With its precise measurement capabilities in specialized fields, the CMM plays an important role in achieving high quality and meeting the stringent requirements of various industries.

When purchasing a 3D CMM (Coordinate Measuring Machine), there are several important criteria to consider in order to select the most optimal device for your actual measurement requirements.

Determine the necessary level of accuracy to meet your measurement needs. This criterion depends on the specific application and varies between industries.

Consider the size and measuring range of the CMM to ensure that it has enough space and capacity to measure your parts or products.

Some complex parts and products require a CMM that is compatible with capabilities such as interchangeable probes and different probing methods.

Automation capabilities, such as automatic sensors, programming functions, and setups for automated measuring processes, can significantly improve measurement efficiency.

The control software should have a user-friendly interface, be easy to use, and integrate modern functions such as automatic reporting.

Choose a CMM supplier that offers quality technical support services, ensuring that any issues during usage are addressed promptly.

Assess your financial situation and choose a model that fits your budget but still ensures quality and flexibility in the measurement process.

Overall, selecting a 3D CMM (coordinate measuring machine) is an important decision that requires consideration of many factors. To ensure you choose the most suitable model, you should consult reputable suppliers. In Vietnam, Yamaguchi Corporation is a leading and trusted entity, specializing in providing industrial measurement solutions for businesses of all sizes nationwide. The trust and support of our customers are a great honor and a significant motivation for Yamaguchi to continually strive to improve the quality and service to best meet the needs of our clients.

HEXAGON is a global technology group established in Sweden. Hexagon has quickly expanded its operations to several Asian countries such as Japan, South Korea, India, and Vietnam. In the field of measurement technology and inspection, Hexagon provides solutions for numerous industries:

Manufacturing Industry: Hexagon offers measurement and inspection solutions for manufacturing processes, quality control, and data management. Their main products include 3D Coordinate Measuring

Coordinate Measuring Machine (CMM), 2D Video Measuring Machines (VMM), laser scanners, robotic arms, and software for automated calculation and analysis.

Electronics and Telecommunications: Hexagon supplies measurement devices for the production of electronic components, ensuring the accuracy and performance of the products.

Aerospace, Marine, Automotive, Motorcycles,...

Supporting industries and molding

And many other industries.

.jpg)

YAMAGUCHI is the exclusive distributor of Hexagon measuring machines. Some of the Hexagon 3D CMM (Coordinate Measuring Machine) products include:

GLORY Bridge-Type CMM – Coordinate Measuring Machine

The GLORY CMM is a new-generation universal measuring machine that delivers high-configuration, flexible, and high-performance measurement solutions. This product is a SPECIAL OFFER from HEXAGON exclusively for the Vietnamese market.

Active vibration damping

Automatic probe change system

Fly2 technology for 3D measuring machines

Scan Pilot enhances accuracy when scanning unknown or complex structures at high speeds

ECO and ECO+ modes

Learn more about GLORY Bridge-Type CMMs at: https://yamaguchi.vn/may-cmm-kieu-cau-glory-bridge-cmms

GLOBAL S 3D CMM

The Global Series is a precise 3D measurement solution, integrated with advanced measuring technologies, flexible for any industrial application.

Learn more about the product at: https://yamaguchi.vn/may-do-cmm-dang-cau-global-series

EXPLORER PERFORMANCE CMM

This product is suitable for measuring products with medium tolerances and has many advantages:

Diverse configurations and sizes.

High rigidity and durability.

Smooth, stable movement.

Heidenhain optical scale that changes linearly with temperature.

Easy installation.

Learn more about the product at: https://yamaguchi.vn/may-do-cmm-explorer-performance

CROMA CMM

Considered a cost-effective measurement solution, it contributes to strict quality management throughout the production process. The combination of structure and technology, especially with the latest software packages, makes CROMA a high-performance product at a reasonable price.

Learn more about the product at: https://yamaguchi.vn/may-cmm-croma-may-do-3d

LEITZ INFINITY ultra-precision coordinate measuring machine

Rated as the most accurate three-dimensional coordinate measuring machine in its segment, LEITZ INFINITY combines optical and touch sensors in a single measurement system to deliver high accuracy measurements.

Learn more about the product at: https://yamaguchi.vn/may-do-toa-do-sieu-chinh-xac-leitz-infinity

YAMAGUCHI is the exclusive distributor of HEXAGON CMM machines in Vietnam. We specialize in providing high-precision measurement solutions for industrial applications with the highest quality standards, accompanied by professional technical support and consulting services.

_1.jpg)

In addition to supplying CMM machines, YAMAGUCHI offers a complete portfolio of metrology equipment and measuring devices. When you choose YAMAGUCHI, you benefit from a comprehensive measurement solution package, including:

Contact Yamaguchi today to experience the difference in industrial metrology products and services. We are committed to providing you with the most accurate and efficient measuring solutions, from consultation and installation to warranty and technical support.

Don't miss this opportunity to receive special offers and enhance your production capabilities with cutting-edge equipment from world-leading brands. Get in touch now for detailed consultation and a competitive quotation!