YAMAGUCHI IS THE EXCLUSIVE DISTRIBUTOR OF HEXAGON.

- Delivery time: 2-4 weeks

- Provide demo machines for trial use

- The widest range of products on the market, suitable for products of small, medium, large, and very large sizes, flat circuit boards, etc. Custom machine designs available upon customer request.

- Enhance measurement efficiency:

+ Software compatible with machines from different manufacturers, featuring offline programming capabilities without the need to stop the machine for measurement setup.

+ Integration of multi-sensor optical and tactile measurement, with Hexagon being the only one to integrate sensors with a rotary axis.

- Diverse origins

- Dealer pricing policy

What is a 2D VMM Measuring Machine? The 2D VMM Measuring Machine is (VMM - Video Measurement Machine) a 2-dimensional coordinate measuring machine, also known as an optical measuring machine, a 2D dimension measuring machine that uses technology to determine coordinates using an optical ruler, resolution camera. High resolution and image recognition software to measure dimensions, details and flat surfaces in two-dimensional space. 2D VMM video measuring machines are often used in the product quality inspection process, measuring the size, accuracy and shape of mechanical components, electronics and other products.

VMM Machine is also known by many different names such as: 2D measuring machine, Image dimensioning machine, Video measuring machine, 2D coordinate measuring machine, Optical measuring machine, 2D VMS measuring machine , VMS machine,…

Hexagon Group was founded in Sweden, is the world's leading brand in the field of industrial measurement with a specialized product range, meeting the highest requirements for precision measurement and inspection equipment.

Hexagon accounts for 70% of the market share of 2D VMM Measuring Machines - VMM Video Measuring Machine in the world.

YAMAGUCHI is the exclusive representative of HEXAGON's VMM machine line. With more than 13 years of establishment and development, YAMAGUCHI has provided many VMM machine models to customers in the fields of Electricity - Electronics, Automobiles, Motorcycles, Aviation, Mechanical Processing, Plastic - Rubber, Telecommunications , Medical,…

.jpg)

Training on VMM products of Hexagon

HEXAGON produces video measuring machine, 2D, 2.5D measuring machines, 3D measuring machines, 2-dimensional coordinate measuring machines with the widest product range on the market, suitable for products ranging from small, medium, to large in size. Special machine models can be designed according to customer requirements.

HEXAGON's optical measuring products help improve measurement performance:

+ VMM meter software can be used on machines from different brands, offline programming feature, no need to stop the machine to set the measurement program.

For example: VMM Video Measuring Machine can use Hexagon's software for Mitutoyo's 2D measuring machines.

The technical department programs the offline measurement program, then sends the program to the measuring machine and the tester conducts the measurement according to the previously programmed program on the 2D VMM Measuring Machine.

+ Ability to integrate multiple optical and touch measuring sensors, only Hexagon can integrate sensors with rotary axis.

2D video measuring machine are used as CNC Measuring Machines and are widely used in factory QC and KCS departments, suitable for all application fields: measuring and testing machinery components, electronics, aerospace, automobiles. Motorcycle tires, molds, tools, gears, terminals, electronic circuit boards, plastic, rubber, measuring watch components,...

Structure of 2D video measuring machine - 2D dimension measuring machine includes the following main parts:

Measurement camera system: Video measuring machine with cameras are considered the most important system for 2D VMM measuring machines. A quality camera system will provide low distortion and high product details to help the software convert data. better, giving more accurate measurement results.

Sample moving table: The VMM machine has a sample holding table, a device that helps move the sample horizontally in the X and Y directions to bring the sample to the camera's operating area as well as move the sample to the edges that need to be measured.

Computer control: Any 2D Measuring Machine needs a controller to run the software, computers running a dedicated operating system are needed to give you access to the company's built-in measurement software. or of a third party.

Measurement software: Video measuring machine - 2-dimensional dimension measuring machine can run different types of software to perform different measurements such as dimensioning, sample edge checking, comparison... so the software can considered part of the device.

The 2D, 2.5D measuring machine operates on the optical principle, using a camera system and software to capture detailed images to be measured. The software will then process the images and calculate measurement parameters based on predefined features and objects.

The video measuring machine product is placed on the surface of the sample stage and moved with a lead screw. The optical ruler attached to the sample stage will provide moving coordinate parameters based on the items, 2D dimension measuring machine software. will combine coordinates and images to give the dimensions to be measured.

In addition, the VMM meter line moves the camera using an air cushion, helping the machine move accurately, and without wear and tear like a mechanical moving system.

2D dimension measuring machine - VMM (Video Measuring Machine - 2-D coordinate measuring machine) is often considered an image dimension measurement system. VMM machines use optical and camera technology to capture detailed images of the object being measured. From these images, the machine will analyze and measure the size, shape and other characteristics of the object accurately.

The 2D VMM measuring machine is a dimension measuring machine that uses a camera system to record videos and images of the details to be measured and magnify it many times to check the shape and measure the size of large-sized samples. Small scale quickly and accurately.

2-D coordinate measuring machine video measurement system mainly has two types: Manual Video Measuring Machine and Automatic Video Measuring Machine.

Manual: With Manual Video Measuring Machine, the part is moved on a manually operated workstation. However, the Z-axis zoom lens can be motorized.

Automatic: In Automatic Video Measuring Machine, the part is moved on motorized CNC stages and a motorized Z-axis zoom lens. Users can create measurement routines, which can be saved and then repeated. This not only speeds up the VMM measurement process, but also ensures that measurements are performed the same way for every part, thereby eliminating operator measurement errors.

.jpg)

Choosing the best 2D measuring machine depends on your application's specific requirements, budget, and other factors. Below are a few product lines of 2D VMM measuring machines with good quality, ensuring reliable accuracy as well as working ability:

Hexagon Manual 2D VMM Measuring Machine - CNC Measuring Machine

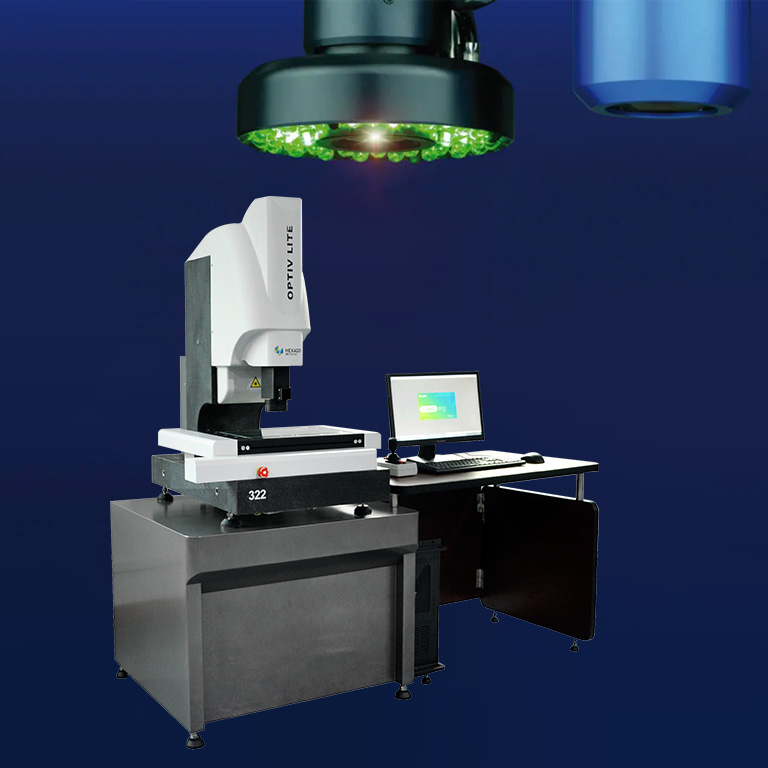

The Optive Lite series of Manual Video Measuring Machine in Hexagon's 2-dimensional coordinate measuring machines is one of the most user-intuitive VMM measuring systems, yet it still provides a reliable accuracy: 3.0 + L/150 µm.

Hexagon's standard automatic 2D VMM measuring machine - CNC measuring machine

2D dimension measuring machine line - automatic VMM measuring machine OPTIV LITE DCC is a fully automatic 2D measuring machine line on all 3 X/Y/Z axes.

Ensures measurement performance as well as high accuracy: 2.8 + L/150 µm.

The intelligent PC-DMIS measurement control software, which extracts information right from the CAD file, has a user-friendly interface, is one of the famous software in the world.

Hexagon Automatic Spherical 2D VMM Measuring Machine - CNC Measuring Machine

The VMM OPTIV LITE OLL DCC meter line is a bridge-type automatic 2D meter line, designed with a long journey suitable for use with large-sized products such as: Solar battery production, household appliances, in the production of PCB electronic components, precision mechanical processing, etc. The machine system is designed to lower the center of gravity, helping to stabilize vibration and increase machine accuracy. In addition, the system applies Hexagon Metrology's patented triangular beam projection technology.

Yamaguchi accompanies customers in developing measurement methods for products, and advises on choosing machine models and accessories that suit each customer's requirements. If you need advice on optical measuring machines, VMM video measuring machine, CMM machines, 2D VMS measuring machines, VMS machines, please contact us for support!