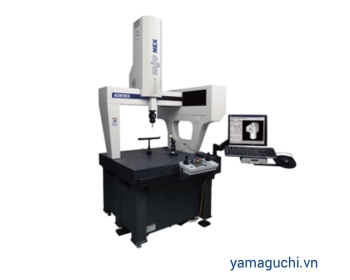

ZEISS MICURA is the solution for new demands in industrial production where parts are becoming increasingly compact and accuracy requirements are rising.

Small and precise

Equipped with the VAST XT gold high-end sensor from ZEISS and navigator technology, ZEISS MICURA offers active scanning with measuring accuracy of less than one micrometer. ZEISS MICURA flexes its muscles, in particular, with small, complex parts featuring narrow tolerances such as those used in optics and electronics. Despite its compact size, this system provides two measuring volumes, 500 x 500 x 500 millimeters and 500 x 700 x 500 millimeter – and therefore considerably more than comparable instruments.

Precise high-speed scanning

The VAST XT gold sensor from ZEISS enables high-speed scanning featuring up to 200 measuring points per second. As a result, form and location parameters such as roundness and flatness can be precisely captured, in addition to geometric features, in a short time. The sensor can be equipped with extremely small stylus tips. The smallest stylus has a diameter of just 0.3 millimeters.

Automatic measuring speed

ZEISS MICURA comes standard with VAST navigator technology. It automatically configures the optimal measuring speed with guaranteed accuracy, thus considerably reducing the measuring time. ZEISS MICURA moves somewhat slower in areas that demand more precision. It moves faster with simple contours or when less accuracy is needed.

The VAST navigator technology also saves time through tangential approach and scanning, helix scanning and fast dynamic stylus calibration.

Operation and ergonomics

ZEISS MICURA comes with a redesigned control panel. One display and two joysticks enable operators to control and program the machine independently of the computer.

The system is easy to operate and makes it possible to start measuring even without in-depth experience with measuring machines. The ledge on the front of the granite table allows the control panel and tools to be stored outside the measuring range.

- Computer-Aided Accuracy: Measuring errors due to dynamically induced inertia effects are automatically compensated for

- Ceramic guideways and a large bearing base minimize susceptibility to external influences

- ZEISS air bearings on four sides guarantee stability and precision

- ZEISS MICURA also comes with two temperature sensor for the workpiece

- The probing force of the sensor is actively regulated and is very low – ideal for sensitive materials

Controller technology, software, sensors and additional components are made by ZEISS and are finely tuned to each other

_thumb_350.jpg)

_thumb_350.jpg)

_thumb_350.jpg)

_thumb_350.jpg)

_thumb_350.jpg)

_1_thumb_350.jpg)

_1_thumb_350.jpg)